Buying an Aljezur farmhouse

Aljezur farmhouses for sale

Algarve west coast climate; the best weather in Europe?

Contact

Odeceixe beach

Control of the red palm weevil

Vicentina natural park wildlife

Heating options

The truth about coastal property

What is natural park Costa Vicentina?

Building and renovating in western Algarve

Portugal land scams

Fishing on the Vicentina coast

Western Algarve agriculture

AFPOP

Utilities in Portugal

Schools in Aljezur

Solar home heating plans

Solar heat start page

Home made stratifier tube, stratification valve, stratifier valve

After a lot of searching, and even consulting with university professors of solar energy, I found this design. it seems to be the only one known to work consistently, but it is not possible to buy it as an individual part.

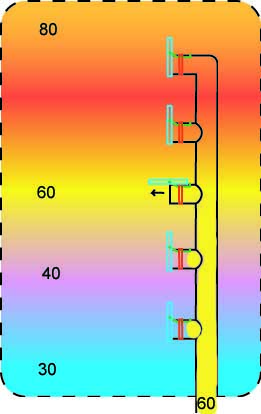

The concept; very sensitive and large format check valves will simply let water into the heat storage tank at more or less the level where water of the same temperature and density is.

Colder, denser water in the bottom of the storage tank will hold the lower valve closed. warmer, lighter water will float above.

In this diagram, heated water is entering the storage tank at 60C.

In this diagram, heated water is entering the storage tank at 60C.The heavier 30 and 40C water in the tank holds the valve flaps closed. The 60 C water does not, however, rise through the lighter column of water above. Since that water is less dense, it "sits" on top as the 60C water enters the tank at the correct level.

To test the principle of this, I built a simple test rig from a steel oil barrel and some plumbing parts. I let water out of the tank from the bottom while introducing new water in through my trial stratification tube.

This is to simulate what would be happening if it were connected to a solar collector.

This is my experimental version, not meant for actual use; the construction of this one isn't robust enough to work for 10 or 20 years in hot water. The pipe is 90mm [4"] PVC drain tube and the flaps are made from "trespa", a material similar to Formica but 6mm [1/4"] thick. It's waterproof and heavier than water.

The first try, in the first photo, didn't work well. Although hot water did exit the top while sucking the bottom closed, the valve only opened an inch or so. the water squeezing through the gap entered the tank at too high a velocity. This is known to cause turbulence, mixing, and loss of stratification.

In the second photo I've made a slight change; the pivot points are drilled into the center of the valve body, instead of using rings behind it. This made for a better balance.

The flap was weighted to have only 2 grams more weight below the pivot than above [when under water]. This worked perfectly.

.jpg)

In this photo, I'm letting 55C water into the 90mm stratifier tube at about 40 liters per minute. the top flap is fully open, water velocity is low. The lower flap, which was hanging slightly open before the flow was started, is now pulled closed, presumably by the venturi effect.

In this photo, I'm letting 18C water into the tank. the layer of hot water floats above as the cold water enters at the bottom, right where we want it.

I used an infrared thermometer to monitor the water temperature through the thin steel barrel. The temperature difference was clearly measurable, although there was a "fade" zone instead of the desired sharp thermocline. I suspect this was a combination of imprecise measuring technique [the steel barrel would conduct some heat from the hot to the cold area] and mixing due to the small size of my test barrel in relation to the large stratifier tube size.

The density of plain water changes only slightly as the temperature rises, so to use the effect the valves have to be very sensitive. A glycol solution would have about twice the effect, but I intend to build a tank in the region of 5 tons, and I don't want to buy 2,500 liters of glycol. And if I did, I would need another 5 ton tank to pump it into in case I needed to modify or work on the heat tank.

With water I can just dump it and pump in new.

It's important that the fluid velocity be low enough to prevent turbulence and mixing, which will cause a loss of stratification.

According to published research, outlet velocity should not be more than 0.15 meters per second. In other words, a very gentle but steady flow.

For 40mm tubing [38mm ID]; 0.192 lps [liters per second] or 11.52 lpm or 691 lph

60mm tubing [56mm ID]; 0.414 lps or 24.8 lpm or 1490 lph

80mm tubing [74mm ID]; 0.547 lps or 32.82 lpm or 1969 lph

The choice of tube diameter will depend on your fluid flow, which is determined by the size of the circulation pump and your solar collector array.

But as a rule of thumb, bigger is better.